BIO CNG

Entrepreneurs working in a renewable energy sector needs to aware of CNG as it is supported by government, environment friendly and is widely used.

Bio Gas - mixture of several gases- it breaks down oxygen and absorb methane and carbon dioxide by dissolving it.

The primary raw material for Bio Gas is agricultural waste, manual waste, green waste, plant material, food waste, sewage resources which is abundant in India.

It can be converted in various renewable automobile fuels such as bio-CNG, syngas, gasoline, and liquefied biogas. On the other hand, Bio-CNG a compressed biogas with high methane content can be a promising candidate as vehicle fuel, which can easily replace conventional fuel to resolve this problem. Methane as a gas serves as fuel and CNG in the highest amount. Biogas is produced by anaerobic digestion with methanogen or anaerobic organisms. which digest material inside a closed system, or fermentation of biodegradable materials.

This closed system is called an anaerobic digester,biodigester or a bioreactor. Biogas is primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulfide (H2S), moisture and siloxanes. The gases methane, hydrogen, and carbon monoxide (CO) can be combustedor oxidized with oxygen. Government has started a program called SATAT, its an initiative for coverting raw wate to produce fuel replacing LPG for various purpose like cooking.

Biogas is produced by anaerobic digestion with methanogen or anaerobic organisms. which digest material inside a closed system, or fermentation of biodegradable materials. Introduction

This energy release allows biogas to be used as a fuel; it can be used for any heating purpose, such as cooking. It can also be used in a gas engine to convert the energy in the gas into electricity.

Biogas can be compressed after removal of Carbon dioxide, the same way as natural gas is compressed to CNG, and used to power motor vehicles. In the United Kingdom, for example, biogas is estimated to have the potential to replace around 17% of vehicle fuel.

It qualifies for renewable energy subsidies in some parts of the world. Bio gas keeps the environment clean, it is called BIOGAS methane. Biogas can be cleaned and upgraded to natural gas standards, when it becomes bio- methane. Biogas is considered to be a renewable resource because its production-and-use cycle is continuous, and it generates no net carbon dioxide.

As the organic material grows, it is converted and used. It then regrows in a continually repeating cycle. From a carbon perspective, as much carbon dioxide is absorbed from the atmosphere in the growth of the primary bio-resource as is released, when the material is ultimately converted to energy.

RAW MATERIAL

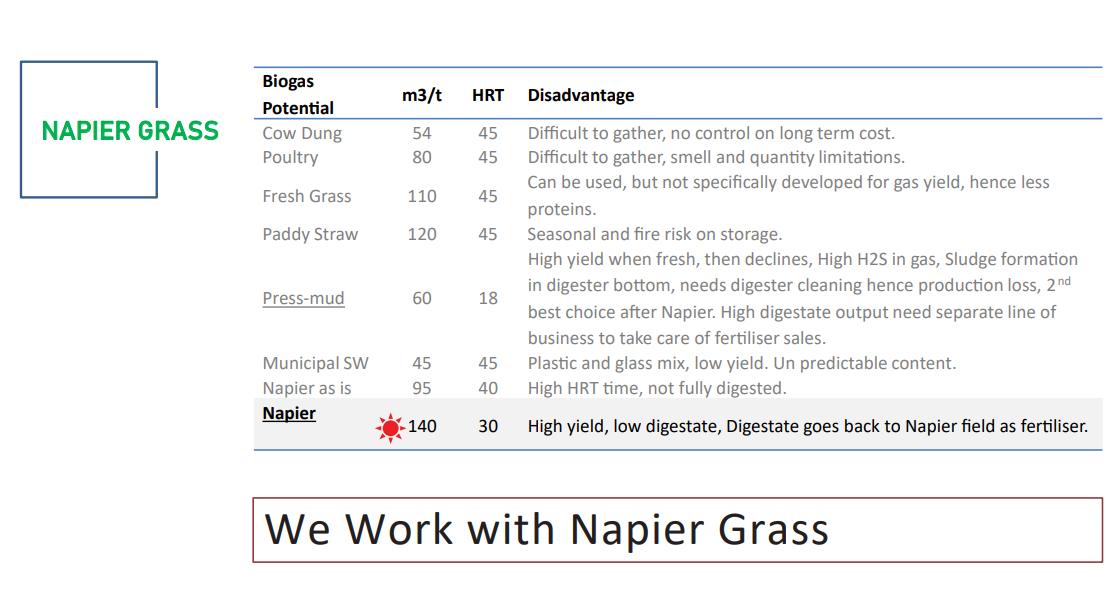

NAPIER GRASS to CBG

Automotive grade fuel under SATAT

Characteristics of Napier

There are different types of Napier available in the agricultural market which is give at most production in least area. The assessment of the production is done by many Scientist, Scientific Labs, Authorized Institutes etc., in which minimum production per acre is 250 ton per year is assessed. It is fastest growing crop according to the production. By planting this crop it is continue to use after 5 to 7 years. It takes less amount of water, fertilizer and energy as compared to the other crops, to which farmer's get more profit. No need to buy seed frequently for the new plantation.

It is harvest process farming. Therefore no expenses for farmer's to buy seeds. Crop harvesting is done 4 or more than 4 times per year, by which farmer's monthly income is fulfilled by three months or less than it. Napier grass is our main raw material for the production unit due to which our production unit get seamless desired supplies.

PROCESS

BioCNG ene to end Green with Napier Grass

Grass - from farmers - doubles their normal Income.

Grass - occupies barren land, locks carbon & releases oxygen. Grass

- Sustainable Input source, round the year, no dependency, any climate/ soil

Improving Rural Economy

- Farmers will get an opportunity to sell the stubble/organic wastes to the Bio CNG

- It will enhance the rural

- Due to the establishment of bio CNG plants, there will be improvements in the rural

- It will play a crucial role in rural

Improving Climatic Conditions

- It will play a crucial role in sustainable development and eco-friendly

- Petrol and CNG imports from other countries will be

- Establishment of this plant will help in carbon footprint

- More control over waste

- It will support Clean India

Napier Grass Harvesting

Harvesting is not dependant on manual labour, nor it is practical to manage, Our Company uses tractor mounted harvesting attachments to harvest the grass from dealers. During cultivation the planning phase ensures that tractor would move around in the field (on a fixed path). Napier being highly invasive and draught resistant and pest resistant the external threats are minimum.

The Harvested grass is further reducing to 3-5mm sized pieces before mixing with water to feed them into the predigesting tanks. Continuous improvement in the verity of grass is expected, as it is also a fodder for cows. Higher the protein higher the milk yield, same is true for the methane, Higher the proteins higher the methane generation.

Sourcing the Grass

The Sourcing will happen within 10-20km distance from the plant. The Grass yields are 180 - 200 ton/acre/year With safety buffer 150 - 200 Acre of fields are required to get the target volume.

Comparative Economics for Farmer:

Average famer earning per Acre: 2 to 2.5 lac Rs./Acre per annum.

Comparison:

Sugarcane :

40 ton per 13 month crop at Rs. 2800 per ton = 1, 03,000/year/acre

Napier :

200 ton (minimum) per 12 month crop at Rs. 1000 per ton = 2,00,000/- (minimum) year/acre with continuous cash flow, with least maintenance.

Transporting the Grass

Pre-shredded grass will be transported to the plant on daily basis on suitable tractors and trucks by the dealers.

Pre Treatment

The Bio Gas plant will have pre-digestion tanks holding the grass. The syrup with fine strands of lignin will be pumped into the digester. The Digester will be fed with doses of *Ferric Compound" to supress the formation of H2S*.Most other feed stocks does not need pre-treatment stage

Digestion

The stages of acidogenesis and methanogenesis will start, as a part of natural biodegradation cycle. 45 days of Hydraulic retention time is maintained. The HRT is managed by controlling the quantity of feed- ing. Our company uses continuously stirred reactor ty digesters.

Gas Generation

Methanogenic bacteria work on the sugars and glucose and release methane, Carbon dioxide and small quantity of H2S. Please note that H2S generation itself is suppressed at this stage though entirely no avoided. The Bio gas gets stored in the top space of the digester. Once filled it flows out of the pipelines.

Biogas will have the following mixture before Purification. Below data is for a 15000kg/day

|

Gas Mix |

Min SCM |

Max SCM |

Average SCM |

Min % |

Max % |

|

Methane |

18615 |

22000 |

20308 |

55.0% |

65.0% |

|

CO2 |

13200 |

10831 |

12015 |

39.0% |

32.0% |

|

Oxygen |

338 |

406 |

372 |

1.0% |

1.2% |

|

Nitrogen |

846 |

677 |

762 |

2.5% |

2.0% |

|

Moisture |

846 |

1185 |

1015 |

2.5% |

3.5% |

|

H2S |

12 |

14 |

13 |

0.0% |

0.0% |

Agitation

Agitation of the content inside the bio-digester is a critical and energy consuming activity. Also agitators are generally expensive and maintenance seeking units. Our technology does not use regular agitators.

We use recirculation of digestate, designed using computerised flow engineering models. The pumps and the metal parts do not come in contact with the rust prone biogas slurry. Even if there is maintenance, nothing needs to stop. Even the break down maintenance can happen in isolation to the normal process.

Bio-Gas to Purified Methane

The pipelines coming out of the digesters carry the bio gas. Raw biogas is collected and stored in balloons. They act as a buffer for the purification unit.

The Bio gas is pass through a scrubbing unit to collect any H2S (50-350ppm), this process will bring down the H2S to 10-15ppm, which is an acceptable limit. Next the Gas is passed though drying unit. Dried gas passes through PSA stage of final purification.

The PSA system absorbs H2S if any, Moisture if any and mainly the CO2. The CO2 can be further purified and used for welding and other industrial applications or be left to the air without guilt. The process is locking more carbon than it releases.

Bio-Gas to Purified Methane

The pipelines coming out of the digesters carry the bio gas. Raw biogas is collected and stored in balloons. They act as a buffer for the purification unit.

The Bio gas is pass through a scrubbing unit to collect any H2S (50-350ppm), this process will bring down the H2S to 10-15ppm, which is an acceptable limit. Next the Gas is passed though drying unit. Dried gas passes through PSA stage of final purification.

The PSA system absorbs H2S if any, Moisture if any and mainly the CO2. The CO2 can be further purified and used for welding and other industrial applications or be left to the air without guilt. The process is locking more carbon than it releases. The Pure methane coming out of the purification system is stored in receiver tanks and Balloons, which act as intermittent storage and buffer for the next compression stage.

Compression

The typical usage pressure in the factory and house hold burners and equipment is 1.2bar at max, but storing uncompressed methane takes huge space. Also any Gas Grid pipeline injection would require us to raise the pressure above the pipeline pressure. Typically the grid pipeline pressure varies from 20-30bar, we can pressurise the gas as suitable for a given case. The CNG bunk supply (Retail Outlet) happens at 200bar pressure in cascades.

One can use mechanical reciprocating compressor or hydraulic compressor. Energy savings to to be the main goal at this stage. We have available supply chain. The advantage with the Hydraulic based compressor is higher life, continuous duty cycle and significant reduction in power consumption. A slightly higher investment on a better technology proves to save a lot of money in-terms of maintenance and power cost. Demonstration The entire concept of Gas using Napier grass or even the bio-CNG itself is a sunrise sector in India. BS6 emission norms have come applicable only since March 2020. Oil marketing companies and automobile companies are switching to CNG/BioCNG engines. There are very few plants running to full capacity in Indian market.

Grass to gas is a proven technology in Germany, US and Thailand. More than 4000 bio-methane plants are running on grass in Europe. Our technology is at par with yields found in Europe and us, which are 10%, yield from the feed stock.

Our own plant will reach their full capacity within 5 years.